Process Principle

Oceans and seas are both a huge captor and an immense reservoir of thermal solar energy. This energy is stored in the water surface layers of tropical seas and oceans. Wind driven currents force this surface water towards high latitudes where it cools down and sinks to the bottom of large oceanic basins. After a long trip in the depths it comes up again to the surface in the so-called "upwelling" regions. Like this the circulation of ocean water transfers heat from the tropical region to the poles regions and then contribute together with atmospheric circulation to the thermal regulation of our biosphere.

This circulation phenomenon explains why the water temperature decreases with depth - even so in the tropical zone. In this zone the ocean water temperature can be greater than 28°C at the surface and uniformly close from 4°C at 1000 meters depth. (See table)

Typical Average Water - Temperature versus Depth (Measured offshore Papeete, French Polynesia)

| Depth in metre | Temperature in °C |

| 20 | 27.2 |

| 100 | 25.3 |

| 200 | 21.4 |

| 400 | 11.1 |

| 600 | 6.5 |

| 1000 | 3.9 |

| 1200 | 3.3 |

The surface water and the deep water of tropical ocean can be used respectively as the heat source and the heat sink of a thermal engine ruled by the Carnot principle.

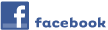

The main components of the system are: Pumps and pipes for supplying the evaporator and the condenser respectively with warm and cold sea water; a working fluid which is vaporized to drive a steam turbine which generates mechanical energy. This mechanical energy can be transformed in electric energy if the turbine is coupled to an alternator.

A very simplified scheme of OTEC process is shown below.

The details of the process and the technology of the components for OTEC systems depend essentially on the choice of the working fluid. There are basically two types of OTEC processes: the closed-cycle and the open-cycle.

In the closed-cycle process the heat from the warm surface sea water is transferred through the evaporator to a working fluid, such as ammonia, at the temperature of the available warm sea water to turn it to vapor. The expanding vapor drives a turbo alternator, which produces electricity. Cold sea water passing through a condenser containing the vaporized working fluid turns the vapor back into a liquid which is then recycled through the system in a "close cycle".

Open-cycle OTEC uses the warm surface water itself as the working fluid. In an evaporator under near vacuum, the water vaporizes at surface water temperatures. The expanding vapor drives a low-pressure turbine attached to a generator which produces electricity. The vapor, which is indeed fresh water vapor, is condensed back into liquid water by exposure to cold temperature from deep ocean water. If the surface condenser keeps the vapor from direct contact with sea water, the condensed water can then be used for drinking water or irrigation. A "direct contact" condenser that mixes the vapor and the cold sea water is more thermodynamically efficient but the effluent is salty and not recycled. The process is repeated with a continuous supply of surface sea water to the evaporator. The cycle of the working fluid is "open".

Variations of OTEC open cycle, include mist lift and foam lift processes, which use a hydraulic turbine instead of the very low vapor pressure steam turbine used in the OTEC open cycle have been proposed and tested at a small scale in the laboratory.

Hybrid systems use parts of both open and closed-cycle systems to optimize the co-production of electricity and fresh water.

To read more about the Principle of OTEC:

- L.Vega, Ocean Thermal Energy Conversion OTEC (parts 1_2 & 3), Hawaii, USA. 2001 at: http://ioa.erl.itri.org.tw

- W. Avery & Wu; "Renewable Energy from the Ocean" A guide for OTEC Oxford U.P. 1994. ISBN 0-19-507199-9.

- Masayuki Mac Takahashi "DOW Deep Ocean Water as Our Next Natural Resource. Terra Scientific Publishing Company. Tokyo. 2000. ISBN 4-88704-125-x.

- Ocean Thermal Energy Conversion and the Utilization of Deep Ocean Water; 2001. Michel A.P. Gauthier. Our Fragile World. Forerunner to the Encyclopaedia of Life Support Systems. EOLSS. ISBN O-9534944-7-0 (http://www.eolss.co.uk).

History of development

Existence of a cold water reservoir under the surface of tropical oceans is known since the mid 1900s and raised interests of intellectuals from that time. With the development of the steam engines the science and technology basis for the production of mechanical energy using a heat hot source and a cold sink of heat at different temperatures were known also.

Credits are given to the novelist Jules Verne for the idea to use surface and deep ocean water to produce electricity (1869 : "Twenty Thousand leagues under the Sea". Chapter XII), to the scientist d'Arsonval for giving the scientific basis of the process (1881) and to the engineer G.Claude for demonstrating its technical feasibility (OTEC experiment - Cuba 1930) and economic potential (Floating OTEC plant "La Tunisie"- Brazil 1933).

G. Claude introducing OTEC Open Cycle to the French "Académie des Sciences". Details of his experiment. Paris, 22 November, 1926

After G.Claude several other projects have been studied mainly in France (OTEC electricity plants in Guadalupe and Ivory Coast-1956) and the USA (J.H-Anderson, 1963). But it is the 1973 oil crisis that triggered, first in the USA and then Japan, the funding of new ambitious projects as the building and test of experimental micro-power plants (Hawaii-1978, Japan -1979 & Nauru-1982), and the studies of OTEC commercial plants of hundreds of MW for electricity or synthetic fuels production.

At the end of the 1970s France launched the project of a 5 MW OTEC electricity pilot plant to be installed in French Polynesia under the contracting authority of CNEXO - le Centre National pour l'Exploitation des Océans, which become IFREMER in 1984 - in partnership with French industry (Alsthom, SPIE-Batignoles, CG-DORIS, FRAMATOME, JEUMONT-SCHNEIDER? SGE-BTP and SGSTE merged in the ERGOCEAN consortium). In 1986 the severe drop in the price of oil led to a worldwide reduction and funding for OTEC development and France decided to abandon the Tahiti project.

In 2000 Saga University of Japan and NIOT of India, announced they agreed to a joint development of OTEC in India, a country with a large access to an abundant OTEC resource that faces a dramatic increase in population and in (clean) energy demand for the future. A one MW OTEC floating plant has been built. The success of this co-operation will certainly be an important milestone in the development of OTEC industry.

The NIOT/Saga University 1 MW closed Cycle OTEC

To read more about the History of the OTEC development

Cuba 1930 OTEC experiment

Floating OTEC plant "La Tunisie"- Brazil 1933

NIOT/Saga University Plant

General OTEC see:

National Renewable Energy Laboratory

Natural Energy Laboratory of Hawaii Authority